artbyrobot

Member

- Joined

- May 5, 2024

- Messages

- 79

- Reaction score

- 57

- Points

- 18

This is my real life terminator/Data from Star Trek/Westworld type humanoid robots project. It is a long term project. I plan to post updates occasionally to share my progress and seek feedback, suggestions, advice, etc. So far I have plans to build Adam, Eve, and Abel robots. All of these are Bible characters. I want the robots to ultimately move like a human, be able to walk, run, jump, do chores, dance, do sports, have conversations realistically, paint, do sculpture, make more robots, etc.

I plan to do most of the electronics custom - so custom microcontrollers, custom motor controllers, custom power supply, custom battery management system, custom sensor support circuitry, etc. I am a electronics beginner so guidance on these parts is welcomed.

Robot Features Planned

I plan to start out making the right arm and hand, rigging them up with servo motors, connecting that up to a pc, and getting it to grasp. From there I will develop the head and torso just enough to be able to code the robot arm to make his other arm and the rest of his own body for me. The bot will have silicone skin and look realistic and move realistic. It will have artificial lungs for cooling. It will have spandex ligaments and cable drive systems to imitate muscles. It will have sensors to feel if it bumps into things and it will have webcam eyes. It will have a speaker in the mouth to speak with and the mouth will move to lipsync what it is saying. It will have facial expressions. It will have advanced artificial intelligence. It will run on battery and/or power cable depending on the situation.

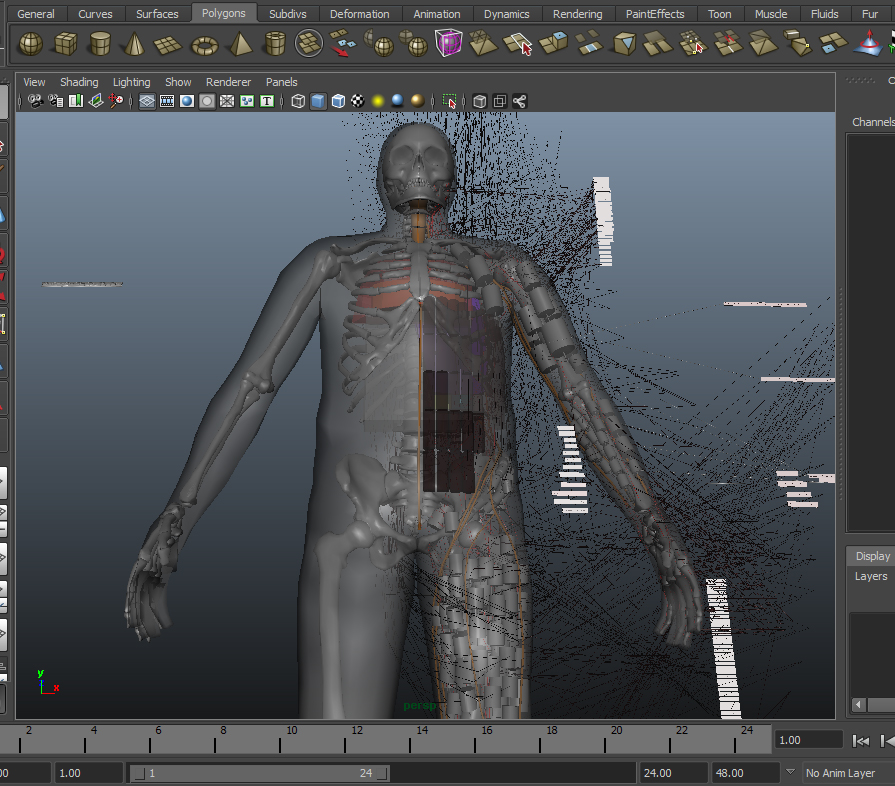

First of all, I ended up caving in and doing a full blown 3d model blueprint of the robot's entire skeletal structure to scale along with outer shape mesh and then modeled out every actuator cable "muscle" and labeled each of them and modeled all of its motors and placed them and modeled various other bits like the main onboard pc and cooling systems (artificial lungs and artificial heart). Also modeled its batteries and placed them. Only had to do half of the body since the other half of body is symmetrical. I realized that with the tight tolerances I'm dealing with, I had to make custom servos and custom pcbs for the servos control and custom pulley systems to "down-gear" the servos. I also realized that with such tight tolerances I needed to 3d model everything to figure out where to fit everything since it will all be a tight fit with little room for error and once I mount a servo, it is a real pain to move it later. The 3d modeling blueprint job was a major project in itself but well worth it in helping me visualize everything better and figure out where to locate everything specifically. I also made blueprints for the motor controller and microcontroller custom circuitry.

Project website: artbyrobot.com

Full humanoid robot building playlist: https://www.youtube.com/playlist?list=PLhd7_i6zzT5-MbwGz2gMv6RJy5FIW_lfn

I plan to do most of the electronics custom - so custom microcontrollers, custom motor controllers, custom power supply, custom battery management system, custom sensor support circuitry, etc. I am a electronics beginner so guidance on these parts is welcomed.

Robot Features Planned

I plan to start out making the right arm and hand, rigging them up with servo motors, connecting that up to a pc, and getting it to grasp. From there I will develop the head and torso just enough to be able to code the robot arm to make his other arm and the rest of his own body for me. The bot will have silicone skin and look realistic and move realistic. It will have artificial lungs for cooling. It will have spandex ligaments and cable drive systems to imitate muscles. It will have sensors to feel if it bumps into things and it will have webcam eyes. It will have a speaker in the mouth to speak with and the mouth will move to lipsync what it is saying. It will have facial expressions. It will have advanced artificial intelligence. It will run on battery and/or power cable depending on the situation.

First of all, I ended up caving in and doing a full blown 3d model blueprint of the robot's entire skeletal structure to scale along with outer shape mesh and then modeled out every actuator cable "muscle" and labeled each of them and modeled all of its motors and placed them and modeled various other bits like the main onboard pc and cooling systems (artificial lungs and artificial heart). Also modeled its batteries and placed them. Only had to do half of the body since the other half of body is symmetrical. I realized that with the tight tolerances I'm dealing with, I had to make custom servos and custom pcbs for the servos control and custom pulley systems to "down-gear" the servos. I also realized that with such tight tolerances I needed to 3d model everything to figure out where to fit everything since it will all be a tight fit with little room for error and once I mount a servo, it is a real pain to move it later. The 3d modeling blueprint job was a major project in itself but well worth it in helping me visualize everything better and figure out where to locate everything specifically. I also made blueprints for the motor controller and microcontroller custom circuitry.

Project website: artbyrobot.com

Full humanoid robot building playlist: https://www.youtube.com/playlist?list=PLhd7_i6zzT5-MbwGz2gMv6RJy5FIW_lfn